Introduction

Choosing the right grinding disc https://www.udo.co.th/category_product/ใบตัดใบเจียร is of utmost importance for achieving precise cuts, smooth finishes, or effective material removal. You can find these versatile tools in all sorts of industries, from construction and metal fabrication to DIY home improvement projects. But with so many different types of grinding discs in the market knowing what each one is for could save you time, energy and money while also making sure that you get the best outcome for your project.

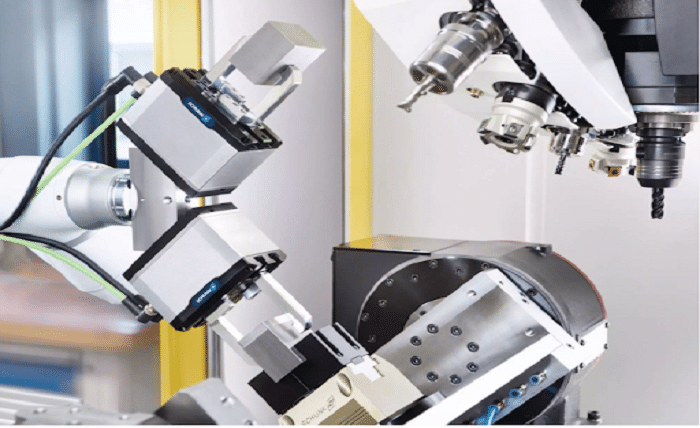

What is a Grinding Disc?

A grinding disc is an abrasive tool used to cut, grind, or polish materials such as metal, concrete, wood, and stone. Grinding discs are built in a range of rotations per minute (RPM), thicknesses, sizes, and grit levels to make them more suitable for specific applications and tasks, and leave behind minimal material build-up and waste, depending on the surface being ground, and vehicle materials being worked with. The choice of disc depends on both the material and the desired finish.

Different Grinding Discs and Their Uses

Choosing the right grinding disc based on the different types available and how they can be employed on your project is very important. There are the following most common options:

- Cut-Off Discs

Cut-off discs are thin, fast rotating discs which are made for cutting through hard materials such as metal, rebar, or pipe. This thin design provides exact, clean cuts with very little material loss. If your project demands straight, precise cuts, a cut-off disc is best.

- Grinding Discs

They are designed for heavy-duty material removal and are thicker and more robust than cut-off discs. These discs work really well for smoothing welds, rust removal and grinding down sharp edges. They are available in different levels of grit, for coarse grinding as well as fine.

- Flap Discs

Flap discs are the crossover point between a grinding disc and a sanding disc. They have overlapping abrasive “flaps” that wear down while you work, exposing new material. This makes blends welds, finishes surfaces and stripes paint or rust ideal for this.

- Diamond Discs

Diamond discs are used for cutting or grinding hard material such as concrete, stone or tile. Equipped with industrial-grade diamonds embedded on these discs, they are high performance and long-lasting.

- Wire Discs

Wire discs are meant for cleaning and surface preparation type applications. They are used for removing paint, rust and debris from metal. The wire thickness can vary in available wire discs for different cleaning intensity.

- Polishing Discs

Used to create smooth and shiny finishes on metal or stone surfaces. These are generally produced from softer like felt or wool and are usually used with polishing compounds.

How to Select The Right Grinding Disc for Your Task

Choosing the appropriate grinding discs cape depends on a multitude of factors:

- Material: Know what material you’re working with: metal, stone, wood, or concrete. Optimize for the right disc type for each material.

- Task: Focus on the task. Are you going to be cutting, grinding, sanding, or polishing? Each task calls for a distinct disc.

- Disc Size: Ensure to match the disc size to your tool. Also when you choose your discs, make sure your grinder can fit them.

- Grit Level: Pick a grit level suitable for the finish. Coarser grits take material away quickly; finer grits give smoother finishes.

Safety Tips for Using Grinding Discs

Grinding discs are critical in many applications, but their high-speed operation has to be complemented with safety precautions.

- Wear Safety Gear: Protective goggles, gloves, and ear protection.

- Click the Disc: Look for cracks or blemishes before use. A fractured disc could disintegrate while in operation.

- Clamp Your Material: Make sure that the material you’re working on is securely clamped down to prevent movement.

- Never exceed manufacturer recommendations: Such as maximum RPM limits, or the intended use of the disc.

Conclusion

Understanding the various types of grinding discs and what they are used for is critical to attaining professional results on your projects. From cutting through metal, to grinding ragged edges, to polishing to a mirror finish, there’s a disc for the job. Selecting the appropriate grinding disc allows you to be more productive and attain desired results with ease!

Quality grinding discs https://www.udo.co.th/category_product/ใบตัดใบเจียร will last longer if you make sure you take the appropriate friction precautions when working. Armed with the right tools, and knowledge, you can take on any project with confidence.